Simulation Of The Impact Of Processing Conditions On The Perovskite Film Morphology

Supervisor(s): Olivier Ronsin, Prof. Dr. Jens Harting

University: Friedrich-Alexander-Universität Erlangen-Nürnberg, HI-ERN (Helmholtz Institute Erlangen-Nürnberg for Renewable Energy)

Type: Master's Thesis

Term(s): SS 2021, WS 2021/22

Keywoards: Renewable Energy, Simulation, Soft Matter, Solar Cells, Theory Project

Abstract

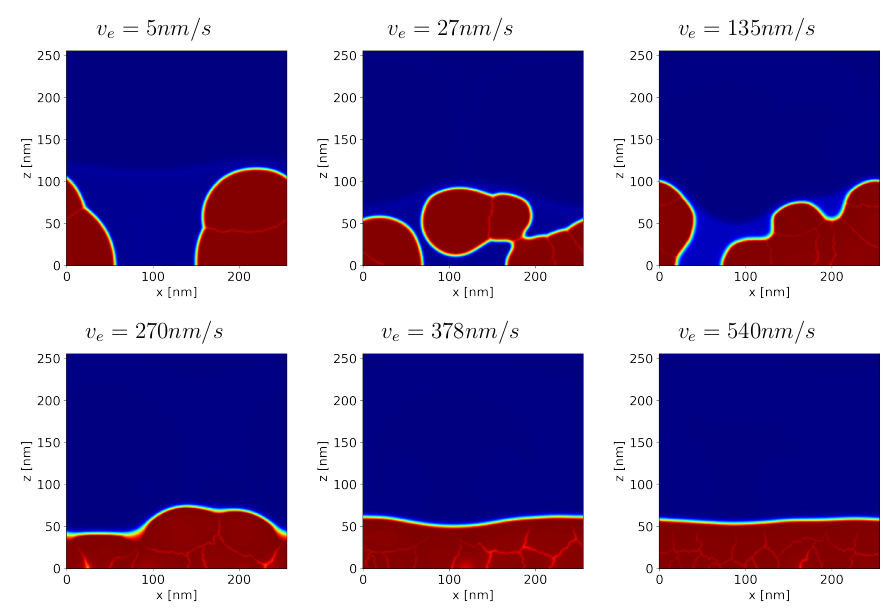

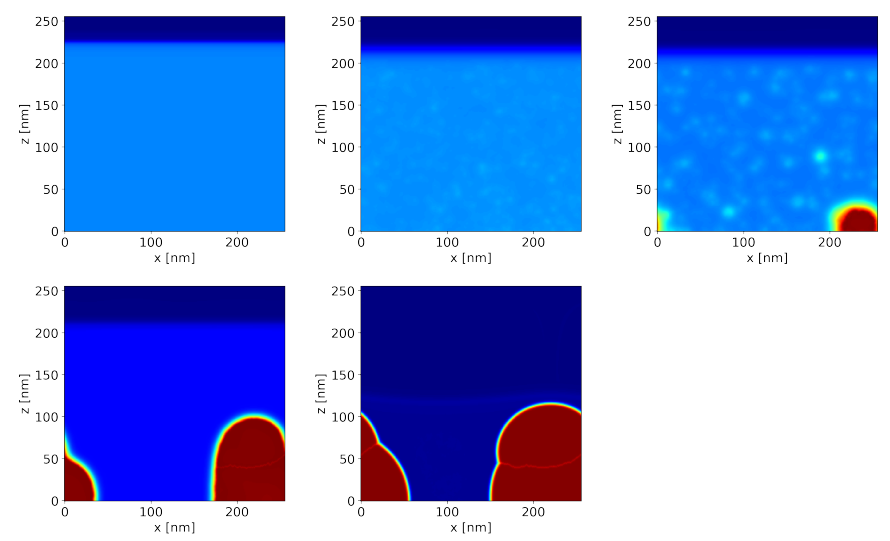

The climate change is a worldwide pressing problem. One little contribution to solve this problem is to investigate new and better solar cells. Solar cells made out of perovskite can be made by printing and could be a low cost, eco-friendly alternative to standard silicon solar cells. Although there has been a huge increase in efficiency over the last years, there is still a gap to silicon. One reason is, that the drying step (from depositing the perovskite-solvent mixture to the dry film) is not really understood and depends heavily on the experimental processing conditions. We try to investigate the effect of the processing conditions, like for example the evaporation rate, with the help of a phase field simulation. This code was developed at the Helmholtz Institute For Renewable Energy Erlangen Nürnberg in the group of Prof. Harting, where I also did my masters thesis.

Simulation

First Results

In these simulations we can vary the experimental parameters and investigate the created film. Additionally, we have a close collaboration to our experimental colleagues from the solar factory of the future and FAU and will be able to compare simulation and experiment soon. The amount of parameters, that can be varied is huge: The thickness of the film, thermodynamic parameters of the materials, the nucleation rate, the crystal growth rate, etc., so there is still a lot to try out for anyone interested in the topic.